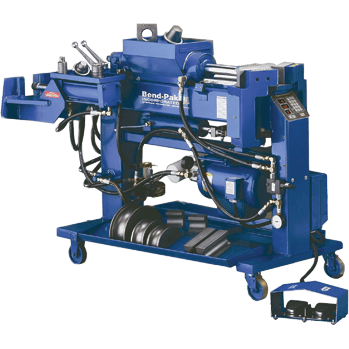

If you find yourself bending a lot of pipe in your shop, then you need an automatic bender with a digital control panel and digital die angle readings right up front. Consider our "Flagship" semi-automatic BendPak 1502BA-202 exhaust pipe bender. We equipped this already top-notch model with an advanced mini-computer and ergonomic control board. The data control board manages all your bending functions—both automatic and manual—and stores up to 99 different bend depths. For an added bit of sophistication, we've also included a remote electric foot switch, so you can control basic bending operations even if you're handling larger tubing 4' away.

Quick-change bending dies

Who has time to waste? Not you. Especially when you have a car in the air and others lined up. Our competitors tried for years to come up with an effective way to swiftly switch out the bending dies. But BendPak actually did it. Our twist-lock tooling and quick-change bending dies are so effective that they are copied across the entire industry. We choose to think of imitation as the best form of flattery, but you should make sure that you get your innovative equipment from the originator and not a knock-off.

180° bending capacity

You told us you needed a bender with an extremely deep bending capability. Is a U-shape deep enough? Thought so. Be sure to ask for our 180° dies if you're planning to bend more than 170°. You'll get perfect deep bends on a 5" radius, without pipe sticking or hang ups. That's because we use an exclusive relief cut design on our bending dies to help maintain the pipe's uniformity throughout the bend cycle and eliminate excessive crimping or deformation.

3" bending capacity

We built a convenient 3" bending capacity into every BendPak bender. In fact, our 3" bending dies perfectly exemplify our commitment to quality. Take a close look at the design. They might look like ordinary bending dies, but these heavy handfuls are anything but. No other manufacturer uses our exclusive step-cut process for the die rails. Our dies feature better-contained large-sized tubing and a more uniform bend. Despite the title of “bender," this unit is actually capable of expanding and flaring too! With a full range of dies to choose from, your big tubing jobs just got a whole lot smaller.

Long-stroke bending cylinder

Because every BendPak bender is equipped with an extended-top cylinder, you no longer need to use pusher block extensions when bending with small-radius dies. Also, the 14" top-cylinder can be retracted further, providing additional clearance for changing dies or removing bent tubing.

Digital control

Hard-core users will appreciate the convenience of our digital control that gives you digital die angle readings right up front. An advanced programmable mini-computer is safely enclosed within the front upright of the bender to allow you to effortlessly fabricate virtually every original equipment exhaust system. The program data control board manages all bending functions, automatic or manual, and stores up to 99 different bend depths.

Clampless swager

All BendPak benders are equipped with our exclusive clampless swager which puts out an incredible force of over 30,000 lbs. for quick and precise end forming. The clampless swager provides rapid set-up time and a high degree of accuracy for I.D. expansions, O.D. expansions, slip-fits, flares, ball-joints, reductions and manifold flanges. All tooling is quick release. Take a close look at the clamp assembly. You won't see a cumbersome, antiquated vise in our clamp assembly. What you will find is American ingenuity at its finest—the narrow hinged collars simply drop into position and allow for flare tubing ends as close as 3" from a bend. Don't worry about troublesome slippage either. The more pressure you put on the clamps, the tighter they grip.

Internal segment expander

Our internal segment expander is just as unique as our clampless swager and can be used for I.D. expansions, O.D. expansions, slip-fits, flares, ball-joints and manifold flanges. The buttress canister has a single position setting for all I.D. expansions, but can also be adjusted for special sizing requirements. A single arbor is used for all tubing sizes 1-1/2" - 3". Combined, the clampless swager and internal expander let you easily perform all end-finishing operations with unparalleled ease: reducing, internal swaging, flares, flat flares, ball-joints, male ball-joints, female sockets, double-donut flares and more. The 1302 models are equipped with a double-ended cylinder for both the clampless swager and segment expander. A single control handle operates the cylinder and is placed towards the middle, so you can stand comfortably in one location and operate both sides.

Electric foot switch

An independent remote foot switch allows you to perform manual bending operations while standing in front of the bending head or up to 4' away. Having the convenience of remote operation is an added plus, especially when handling larger tubing. Switches are industrial-grade quality and covered for your protection.

Industrial-grade hydraulic cylinders

Integrated into every BendPak bender are commercial-grade hydraulic cylinders that feature a single-piece, pilot-fitted, machined-steel piston, wrapped with specially designed, pressure-loaded U-cup piston seals, backups and wear bands to virtually eliminate fluid bypass. The micro-smooth chrome-rod is machined from high-yield, ground and polished C-1045/50 micro-alloy steel and plated to a minimum of .001" diametrically, to ensure superior cylinder operation and life. The superior-design high durometer, mechanically-loaded rod seals make rod leakage is a thing of the past while a specially formulated abrasion-resistant urethane rod wiper provides exclusion protection. The welded cylinder body is made from robust steel tubing produced to exceed ASTM specifications. This combination of superb base material and superior processing ensures that the cylinders remain straight, smooth and last a very long time.

Durable powder coat finish

All BendPak benders feature a durable powder-coat finish that gives the metal a high-quality, extremely durable finish which can withstand even the harshest environmental or chemical conditions. Unlike other companies that claim to powder coat, we take pride in our meticulous 10-step process. First, all parts are visually inspected before being sandblasted. Afterwards, the parts are washed in our 5-stage phosphate tanks that can accommodate parts up to 25' long. Once cleaned, they're immediately dried to avoid rust production, and then outgassed. Outgassing pre-bakes the parts in a curing oven, reducing the possibility of blemishes that may be hiding in the pores of the metal. If not properly outgassed, imperfections in the metal may bubble during the curing process and most likely will cause chips in the powder. After the parts are washed and outgassed, any surfaces and / or threaded holes that need to be masked or plugged, are done so with high-temperature masking tape and silicone plugs. Next, the parts are given a quick thinner wipe to remove any light debris or fingerprints, before being hung on an electrostatically grounded conveyor line. The powder is finally applied using an electrostatic spray gun. The powder “sticks" to the surface in a fashion similar to how dust sticks to a television screen. Once the parts are powder coated, the carts are rolled into our curing oven and baked at 400° F for 45 minutes.

Optional step-by-step digital user guide

Our exhaustive BendData program features over 10,000 bending applications. The simple computer program system guides you through every step of exhaust and tailpipe fabrication. Coverage includes domestic and light trucks as far back as 1965.

- 2 separate end-finishing units at rear for all necessary flaring and expanding

- Dual-unit expander

- Digital control for automatic or manual bending operations

- 202 Standard Tooling Package included

- Comes complete with quick release bending and finishing dies

- Includes high-speed clampless swager and internal expander

- Easy-to-use drop-in collar makes swaging operations quick and efficient

- Twist-lock tooling

- Integrated power-relief control valve

- Pass-through cylinder stem passes completely through the primary frame

- Rigid 6" x 6" x 3/8" welded-steel tube frame

- Commercial-grade hydraulic cylinders

- All cylinders feature chrome-molly shafts, conforming to ANSI 92.2 standards

- Quick-release bending dies for reduced set-up times

- Bending heads precision grounded to within .002"

- Enclosed controls keep your bending area clutter-free

- 2-1/2" oversized barrel shafts for maximum dependability and minimum maintenance

- Standard grease fittings allow for simple lubrication

- NEMA rated on / off switch box incorporates overload relays that automatically disrupt power supply should an unforeseen over-current situation occur

- Pressure gauges let you know exactly what the system pressures are at all times

- Industrial grade casters help you easily move the bender around your shop

- Remote foot operated controls for added long-distance control

- Adjustable pressure valve located right up front

- One piece barrel ensures that the bending gates stay perfectly aligned with the ram

- Heat-treated tooling for greater service life

- Convenient tool trays keep your tooling organized

- Strong, 5 Hp Baldor energy efficient motor delivers maximum performance

- Direct-drive, high-speed, 4 gpm pump

- Single enclosed bottom cylinder applies pressure evenly to the back gates and, because it is hidden, does not interfere with the tubing

- Large capacity fluid reservoir keeps the hydraulic oil running cooler and prevents contamination

- Canister oil filter in the hydraulic system keeps the oil nice and clean

- Oil sight-gauges allow you to visually inspect oil levels

- Over-sized 1/2" high-pressure hose provides better speed and cooling

- Open-sided swager box allows for easier access and reduces the chance of "crashing" tools and damaging the cylinder

- 180° bending die available

- Bending controls: automatic / digital control

- Expander controls: manual / knee lever

- Frame style: 1502 / dual expander units

- Maximum bending radius: 5" / 127 mm

- Minimum bending radius: 3-1/3" / 89 mm

- Maximum tube capacity: 3" / 76 mm / .095 wall

- Standard die pack (202): 1-1/2", 1-3/4", 2", 2-1/4", 2-1/2"

- Top cylinder working force: 60,000 lbs. / 27,216 kg

- Hydraulic filter: canister

- Dimensions: 41" x 64" x 26" / 1,041 mm x 1,626 mm x 660 mm

- Standard motor: 5 Hp / 208 - 230 VAC / 60 Hz / 1 pH

- Shipping weight: 1,300 lbs. / 590 kg

- Shipping dimensions: 48" x 70" x 30" / 1,219 mm x 1,778 mm x 762 mm

Featured accessories for the 1502BA-202

Quick Specs

| Bending controls: | Automatic |

| Expander controls: | Manual |

| Frame style: | 1502 |

| Max. bending radius: | 5" |

| Min. bending radius: | 3-1/3" |

| Tube capacity: | 3" |

| Standard die pack: | 202 |

| Shipping weight: | 1,300 lbs. |