Parts washers explained - The Deep Clean advantage

Ranger™ front loading parts washer cabinets are fully integrated  commercial parts washing systems for auto-repair shops, manufacturers, or other industrial parts cleaning applications. Our automatic parts washing systems help your business run smoothly and safely, while at the same time protecting the work environment by using heated aqueous technology combined with a water soluble detergent solution instead of hazardous solvents.

commercial parts washing systems for auto-repair shops, manufacturers, or other industrial parts cleaning applications. Our automatic parts washing systems help your business run smoothly and safely, while at the same time protecting the work environment by using heated aqueous technology combined with a water soluble detergent solution instead of hazardous solvents.

Technicians simply load dirty parts into their Ranger parts washer, turn a knob, and walk away - it’s that simple. Within 15 minutes or less those once filthy parts are grime-free and ready to go. No harmful solvents, no laborious brushing or hand cleaning, no health hazards or hazardous solvents – no problem.

Technicians simply load dirty parts into their Ranger parts washer, turn a knob, and walk away - it’s that simple. Within 15 minutes or less those once filthy parts are grime-free and ready to go. No harmful solvents, no laborious brushing or hand cleaning, no health hazards or hazardous solvents – no problem.

Ranger parts washers are generally used to  clean transmissions, engines and engine parts, industrial machinery, brake drums, wheels, or other parts in desperate need of a bath. Ranger high-pressure parts washers clean by using a combination of high pressure multi-directional spray nozzles and a heated aqueous based detergent solution. Alloy spray nozzles positioned along the interior wall, ceiling and underside of the cabinet and turntable spray heated high-pressure streams of cleaning solution at the objects loaded inside the massive front-loading cabinet. A low RPM turntable provides 360-degree cleaning.

clean transmissions, engines and engine parts, industrial machinery, brake drums, wheels, or other parts in desperate need of a bath. Ranger high-pressure parts washers clean by using a combination of high pressure multi-directional spray nozzles and a heated aqueous based detergent solution. Alloy spray nozzles positioned along the interior wall, ceiling and underside of the cabinet and turntable spray heated high-pressure streams of cleaning solution at the objects loaded inside the massive front-loading cabinet. A low RPM turntable provides 360-degree cleaning.

T he recommended temperature range for Ranger parts washer systems will vary according to the thermostat setting and chemicals used. We find that our parts washers operate best in the 140° to 180° F range. (If the water temperature is too hot, water loss is increased due to higher evaporation.)

he recommended temperature range for Ranger parts washer systems will vary according to the thermostat setting and chemicals used. We find that our parts washers operate best in the 140° to 180° F range. (If the water temperature is too hot, water loss is increased due to higher evaporation.)

All Ranger industrial parts washers  have a built-in purifying-recycling system enabling the detergent solution to be recycled and reused over and over to help minimize operating expense. The purifying-recycling system works by skimming oil from the solution and discharging the sludge into a separate disposal container. Ranger’s disk skimmers feature a parallel shaft gear motor that is sealed and rated for continuous operation. A stainless steel disk eliminates warping typically associated with plastic discs. The washer oil skimmer features a deep sump collection reservoir, stainless steel wiper blades and a steel trough that directs used oil and contaminants to a collection container.

have a built-in purifying-recycling system enabling the detergent solution to be recycled and reused over and over to help minimize operating expense. The purifying-recycling system works by skimming oil from the solution and discharging the sludge into a separate disposal container. Ranger’s disk skimmers feature a parallel shaft gear motor that is sealed and rated for continuous operation. A stainless steel disk eliminates warping typically associated with plastic discs. The washer oil skimmer features a deep sump collection reservoir, stainless steel wiper blades and a steel trough that directs used oil and contaminants to a collection container.

In addition, a large debris filter screen is also used to remove larger particulate matter before it enters the solution tank to help maintain solution purity and cleaning performance. These integrated systems enable the user to reuse the detergent solution several times before requiring a refill. Because the detergent solution is water based, the final batch of solution can be evaporated or drained leaving just the grease and other sludge within the tank for proper EPA disposal.

In addition, a large debris filter screen is also used to remove larger particulate matter before it enters the solution tank to help maintain solution purity and cleaning performance. These integrated systems enable the user to reuse the detergent solution several times before requiring a refill. Because the detergent solution is water based, the final batch of solution can be evaporated or drained leaving just the grease and other sludge within the tank for proper EPA disposal.

When searching for an automotive or  commercial parts cleaning system, businesses should evaluate equipment models and detergent types to best suit their needs. Always start by determining the weight and size capacity needed for today’s demands as well as tomorrow needs. The right choice will be a combination of parts washer and cleaner that is safe, effective, and convenient while minimizing running expense.

commercial parts cleaning system, businesses should evaluate equipment models and detergent types to best suit their needs. Always start by determining the weight and size capacity needed for today’s demands as well as tomorrow needs. The right choice will be a combination of parts washer and cleaner that is safe, effective, and convenient while minimizing running expense.

Parts cleaning laws and guidelines

By first researching regulatory responsibilities, businesses can avoid costly investigation and compliance problems later. Even when using commercial parts washers like our Ranger aqueous systems, testing and approval from waste water treatment agencies is required prior to disposal down the sewer drain. Before deciding on a parts washing system, be sure you fully understand the regulatory advantages and disadvantages of each type.

By first researching regulatory responsibilities, businesses can avoid costly investigation and compliance problems later. Even when using commercial parts washers like our Ranger aqueous systems, testing and approval from waste water treatment agencies is required prior to disposal down the sewer drain. Before deciding on a parts washing system, be sure you fully understand the regulatory advantages and disadvantages of each type.

Whether aqueous or petroleum-based, parts washer solution and waste must be managed as a hazardous disposal - unless an official evaluation deems the waste non-hazardous. Waste evaluation may consist of a chemical ingredients declaration and full disclosure of the contaminants introduced to the cleaning solutions during cleaning -sometimes, additional testing may be required. If your parts cleaner service or supplier does not address regulatory concerns that apply to your parts washer, consult with your hazardous waste regulatory program for assistance. Failure to gain the necessary approvals prior to disposal of parts cleaning wastes can result in enforcement action and other liabilities.

There are several different parts washing systems on the market ranging from simple bench style cleaning tanks, to sophisticated free-standing front-loading cabinet styles. Determine which system is best for your shop based on the type and quantity of parts that are routinely cleaned, as well as the type and amount of grime that will be present.

Aqueous vs. petroleum-based

Water-based detergent solutions found in aqueous parts washers are typically less hazardous to users and those in close proximity to the work area than petroleum-based types. Water-based parts washers like the Ranger RS-500 or RS-750 typically use a powdered or liquid detergent that includes a corrosive ingredient such as alkaline and other less corrosive chemicals to remove soil, grease and grime from parts.

washers are typically less hazardous to users and those in close proximity to the work area than petroleum-based types. Water-based parts washers like the Ranger RS-500 or RS-750 typically use a powdered or liquid detergent that includes a corrosive ingredient such as alkaline and other less corrosive chemicals to remove soil, grease and grime from parts.

Petroleum-based parts cleaning systems use petroleum-based solvents such as mineral spirits, Stoddard, or kerosene. Though mineral based solvents are effective cleaning agents, they have been banned in many areas because they give off Volatile Organic Compounds (VOCs). VOCs are a major cause of urban air pollution, and many contain compounds that are toxic and have health risks associated with long term exposure. Long term exposure to these concentrated vapors can cause coughing, choking, inflammation of the nose, throat, and upper respiratory tract, and in severe cases, pulmonary edema, circulatory failure, and death. Because petroleum-based solvents are ignitable, shops using these volatile cleaners must take extra precaution when using and storing the solution and managing the wastes.

are effective cleaning agents, they have been banned in many areas because they give off Volatile Organic Compounds (VOCs). VOCs are a major cause of urban air pollution, and many contain compounds that are toxic and have health risks associated with long term exposure. Long term exposure to these concentrated vapors can cause coughing, choking, inflammation of the nose, throat, and upper respiratory tract, and in severe cases, pulmonary edema, circulatory failure, and death. Because petroleum-based solvents are ignitable, shops using these volatile cleaners must take extra precaution when using and storing the solution and managing the wastes.

By comparison, Ranger’s water-based aqueous cleaning  solution has very low VOC ratings making it a better choice than solvents in areas with air quality concerns. Our Aluma-Klean water-based powdered detergent is also nontoxic, nonhazardous and nonflammable. Contaminants in the water are removed mechanically with our built-in oil skimming system, or concentrated by evaporating away most of the water. Like any industrial parts washing system, the cleaning solution has to be monitored and maintained for optimum cleaning performance. This means adding make-up water periodically, monitoring the concentration of the cleaning solution, and using the skimmer and remove large particulates form the filter screen to extend the life of the solution.

solution has very low VOC ratings making it a better choice than solvents in areas with air quality concerns. Our Aluma-Klean water-based powdered detergent is also nontoxic, nonhazardous and nonflammable. Contaminants in the water are removed mechanically with our built-in oil skimming system, or concentrated by evaporating away most of the water. Like any industrial parts washing system, the cleaning solution has to be monitored and maintained for optimum cleaning performance. This means adding make-up water periodically, monitoring the concentration of the cleaning solution, and using the skimmer and remove large particulates form the filter screen to extend the life of the solution.

Petroleum-based cleaning systems have declined dramatically in recent years due to stricter regulatory demands. From a risk perspective, more and more workplaces are choosing water-based cleaning systems because they are environmentally friendly and less hazardous.

See the material data safety sheet on Ranger's Aluma-Klean recirculating detergent.

Automotive

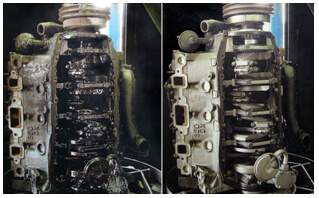

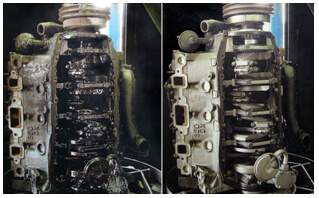

Regardless of what kind of engine or transmission work you do, pre-cleaning the parts is almost always first on the list. Parts should be cleaned before they are reassembled, repaired or machined for a variety of reasons - it helps maintain a clean work environment, cleaning uncovers bare metal surfaces making hairline cracks and other flaws more visible, and it creates a clean surface that can be painted or coated later. Thorough cleaning is also one of the last steps you should consider after parts have been machined or resurfaced. Although initial cleaning will remove any accumulated grime, the second cleaning will be effective in remove any remnant cutting lubricants or metal chips and grinding debris from the ready parts. Final cleaning is always important because debris not washed away can end up inside the engine or transmission.From a business perspective, cleaning costs need to be fully understood and calculated. The labor and expense that goes into cleaning can account for 10 percent or more of the total cost to rebuild an engine or transmission. In some shops, parts cleaning may account for as much as 30 percent when you factor in time, labor, the cost of the cleaning equipment, cleaning chemicals and disposing of the waste. Compared to shops specializing in performance work on racing engines with mostly new parts, cleaning represents a higher expense for those shops specializing in older engine or transmission repair due to years of accumulated debris.

Whether you’re removing years of accumulated grime or just washing parts for that factory fresh look, every engine and transmission builder needs to periodically review the cleaning process to make sure the procedures are working well and void of any cleaning issues or irregularities.

Reducing cleaning and waste disposal costs

One of the hidden costs of cleaning engine parts, transmission parts or other machinery components is disposing of the used chemicals and other wastes that are leftover from the cleaning process. With any type of aqueous cleaning system, sludge and oils inside the tank or parts washer cabinet have to be filtered, skimmed or removed as prescribed and mandated by regulatory agencies. According to

One of the hidden costs of cleaning engine parts, transmission parts or other machinery components is disposing of the used chemicals and other wastes that are leftover from the cleaning process. With any type of aqueous cleaning system, sludge and oils inside the tank or parts washer cabinet have to be filtered, skimmed or removed as prescribed and mandated by regulatory agencies. According to

Resource Conservation and Recovery Act (RCRA) regulations, a substance is classified as waste when it is no longer a usable product. A barrel of caustic or a drum of degreasing solvent is not a waste as long as it is still being used to clean parts (or is being stored for future use or reuse). But once a cleaning product becomes contaminated with sludge and is removed from the cleaning equipment, it becomes "waste" and may be subject to hazardous waste storage and disposal regulations if it contains any ingredients that make it hazardous.

The EPA publishes a lengthy list of chemicals that are considered hazardous. Generally speaking, a material must be labeled hazardous if it contains more than the allowable amount of:

-

Corrosives such as strong acids (phosphoric, hydrochloric, etc.) or caustics (sodium hydroxide) that have not been neutralized. This would be determined by measuring the pH of the liquid.

-

Toxic or poisonous chemicals (most petroleum distillates & solvents).

-

Organic solvents or chlorinated hydrocarbons (such as methylene chloride or carbon tetrachloride).

-

Explosive or flammable chemicals with a flash point of less than 140° F). This would include most solvents, benzene, aromatic hydrocarbons, mineral spirits, toulene, naptha, ketone, alcohols, paint thinner, etc.

-

Heavy metals (lead, mercury or cadmium). This would include contaminated shot blast, oven ash, cleaning solutions and sludge.

-

Cyanide from electroplating or metal treating operations.

-

Any other substance that the EPA, Department of Transportation or state regulatory agencies have labeled hazardous or toxic.

Any machine shop that generates more than 220 lbs. of hazardous waste per month is considered a "Small Quantity Generator" (SQG). The 220 lb. figure includes all solid and liquid hazardous waste generated by all aspects of your business, including any additional facilities (such as an installation service or warehouse that you might also operate). If you are a SQG, then you must comply with all the various federal, state and local laws regulating on-site storage, transport, disposal and/or treatment of hazardous waste.

To reduce waste disposal issues, the cleaning solution in our heated aqueous systems can be evaporated to reduce the volume of the waste water as much as possible before disposing of the slurry. Evaporation can reduce 1,000 gallons of spent cleaning solution down to 50 gallons of sludge.

We're here to help

Our experienced service team will be happy to assist you in helping solve your commercial parts washing problems by evaluating your specific request and selecting the parts washer that best suits your needs.

We don't want to just sell you an auto parts cleaning system, we want to help you solve your parts cleaning problems. Call us today for a free consultation and let our courteous sales team help you choose just the parts cleaning system that will make your dirty problems go away.